Bearing classification

Sliding bearing

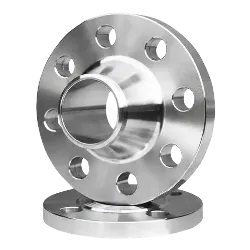

Sliding bearings have no inner and outer rings and no rolling elements. They are generally made ofWear-resistant materialsmade. It is often used in low speed, light load and mechanical rotating parts where lubricating oil and maintenance are difficult.

Spherical bearing

The sliding contact surface of the spherical plain bearing is spherical and is mainly suitable for swing motion, tilting motion and rotational motion.

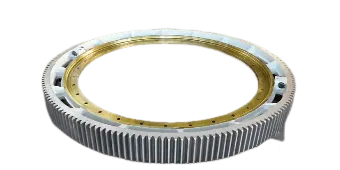

rolling bearing

-

Rolling bearings are divided into different categories according to the load direction or nominal contact angle they can bear.Radial bearingsandthrust bearing. inRadial contact bearingsis a radial bearing with a nominal contact angle of 0,Radial angular contact bearingsIt is a radial bearing with a nominal contact angle greater than 0 to 45.Axial contact bearingIt is a thrust bearing with a nominal contact angle of 90. A thrust angular contact bearing is a thrust bearing with a nominal contact angle greater than 45 but less than 90.

-

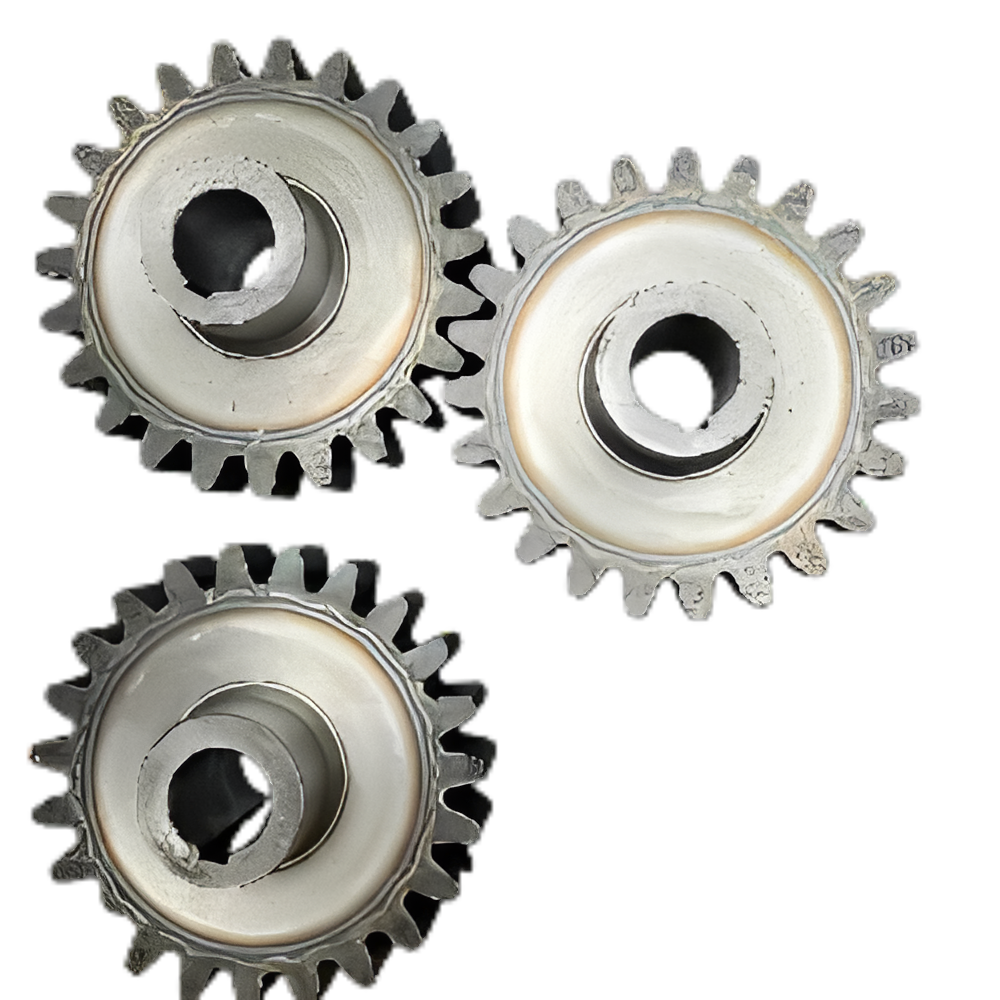

According to the shape of the rolling element, it can be divided intoball bearingandRoller bearing. Roller bearings are divided into: according to roller type:Cylindrical roller bearings,Needle roller bearings,Tapered roller bearingsandSpherical roller bearings.

-

According to whether they can adjust their concentration when working, they are divided intoAligning bearings----The raceway is spherical and can adapt to the angular deviation and angular motion between the two raceway axis lines and non-aligning bearings (Rigid bearing)----Bearings that can resist the angular offset of the axis between the raceways.

-

-

according torolling elementThe number of columns is divided intoSingle row bearing,Double row bearingsandmulti-row bearings.

-

According to whether its components (rings) can be separated, they are divided into separable bearings and non-separable bearings.

-

It can also be divided into various structural types according to its structural shape (such as whether there is a filling groove, whether there is an inner and outer ring and the shape of the ferrule, the structure of the rib, and even whether there is a cage, etc.).

-

According to its outer diameter size, it is divided intominiature bearings(<26mm), small bearings (28-55mm), small and medium bearings (60-115), medium and large bearings (120-190mm), large bearings (200-430mm) and extra large bearings (>440mm).

-

-

Divided by application areasMotor bearings,Rolling mill bearings,main bearingwait.

-

Divided by materialceramic bearings,plastic bearingswait.

-